Chengtai has an annual production capacity exceeding 10,000 units. We take serious Quality Control on material sourcing utilizing the best manufacturing processes and employees for machining processes, heat treatments, grinding operations, assembly processes, and also final-product testing processes.

RAW MATERIALS

Chengtai uses premium steel ingots and raw materials that get forged completely. We have a strict testing system that quality inspectors would check every material before processing.

FACILITIES & MACHINING

Chengtai continuously invests in Korean machineries and Japanese facilities which include fully-automated CNC horizontal and vertical drilling, milling machineries, horizontal grinding and piston grinding facilities. Chengtai’s unrivaled facilities maximize the production efficiency and produce the most precise components that have near 0 tolerances for errors.

HEAT TREATMENT

Chengtai has one workshop only for heat treatment with more than 10 furnaces to achieve all heat treatment technical requirements such as carburizing, normalizing, nitriding, and tempering.

After first-round machining, Chengtai must use heat treatment facilities to increase the hardness of each spare part in order to ensure the reliability of breakers under the harshest application conditions.

Chengtai has a real-time digital monitoring system that controls the quality during heat treatment.

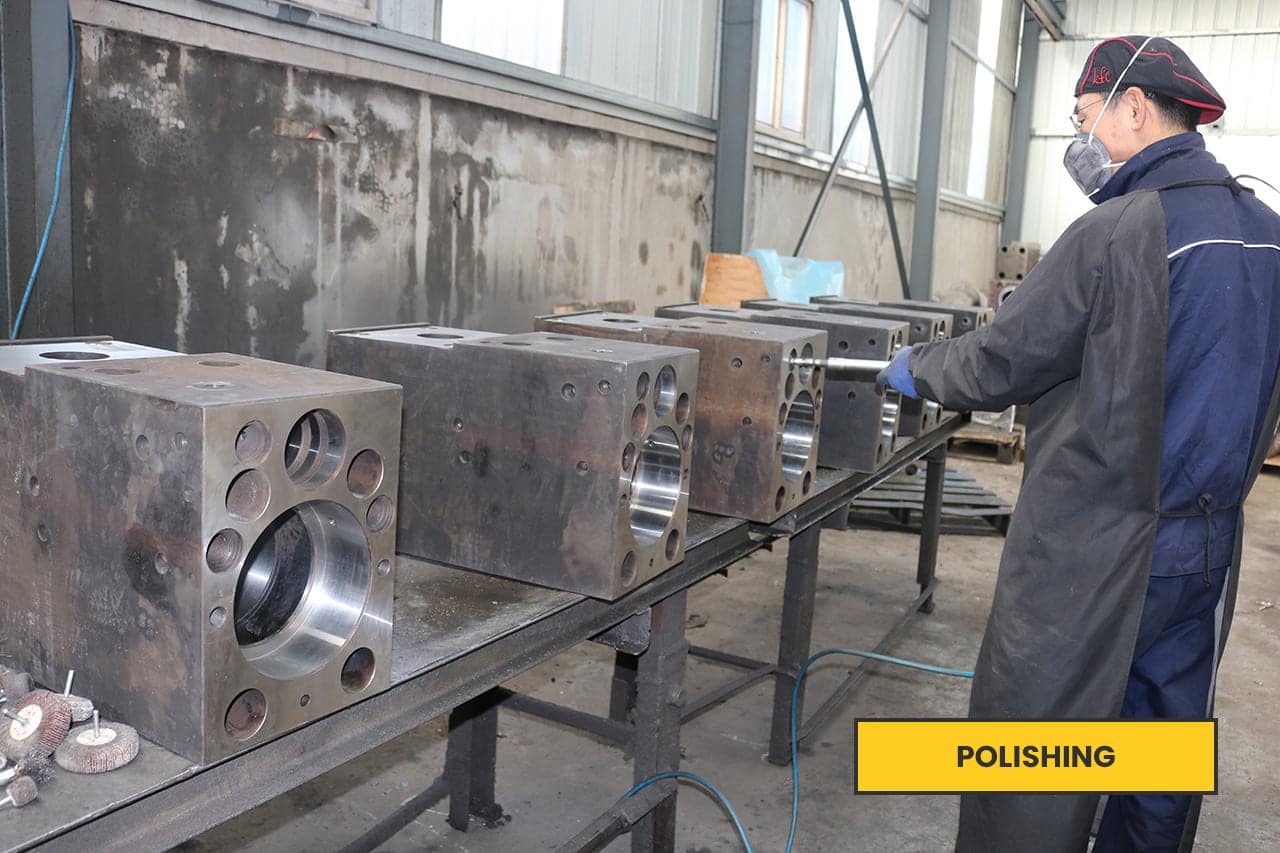

FINISHING, MACHINING & ASSEMBLY

After heat treatment, cylinders are necessary to undergo horizontal and vertical grinding and polishing inside of cylinders by hand tools ensuring every inch of cylinders are polished well to achieve the best possible quality.

HYDRAULIC IMPACT TEST

After the main body gets assembled, a hydraulically pressured test is essential. This step determines if a hammer meets production standards and quality requirements. This extra test offers our customers the essential trust and confidence when selecting Chengtai as their supplier.

SUPPORT & INSTRUCTION

Chengtai admits that a successful factory needs to offer customers excellent support and instructions. We develop sophisticated after-sales support. Customers will receive all the following: certificate of qualification, brochure, warranty list and operation guide and so be a confident and a happy customer of Chengtai.

PACKAGING & SHIPPING

Our products are packaged in plastic cloth, tensile membranes, steel tape, and wooden box. Plastic Cloth and tensile membranes can prevent breaker from rusting when long-time shipping on the sea. Steel tape and outside wooden box can protect breakers from collision to ensure a safe delivery to our products.